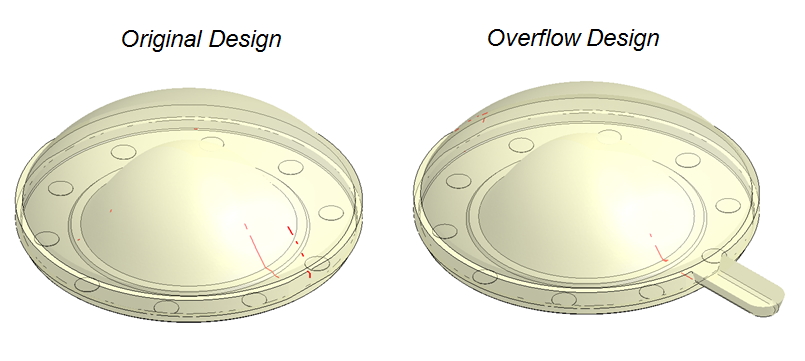

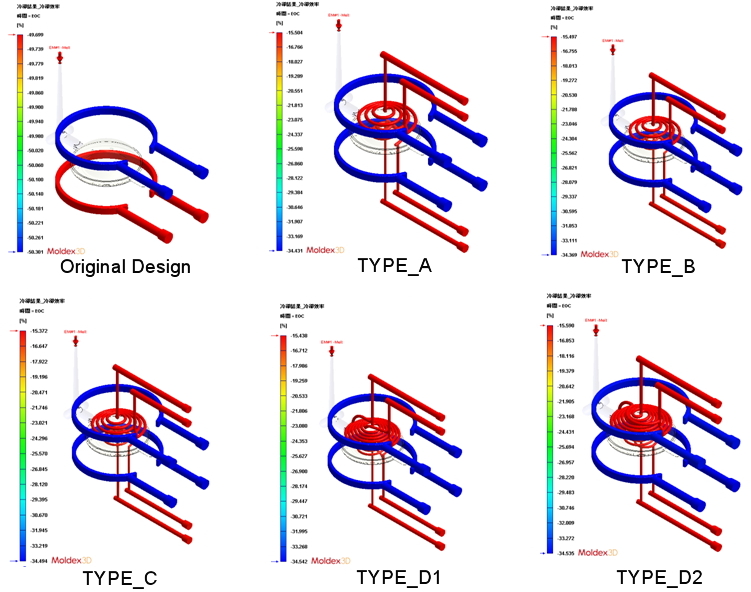

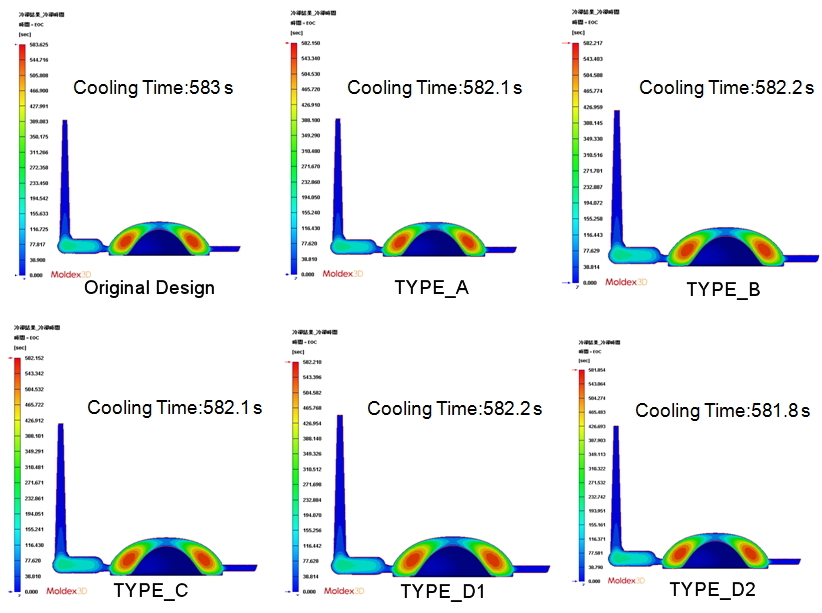

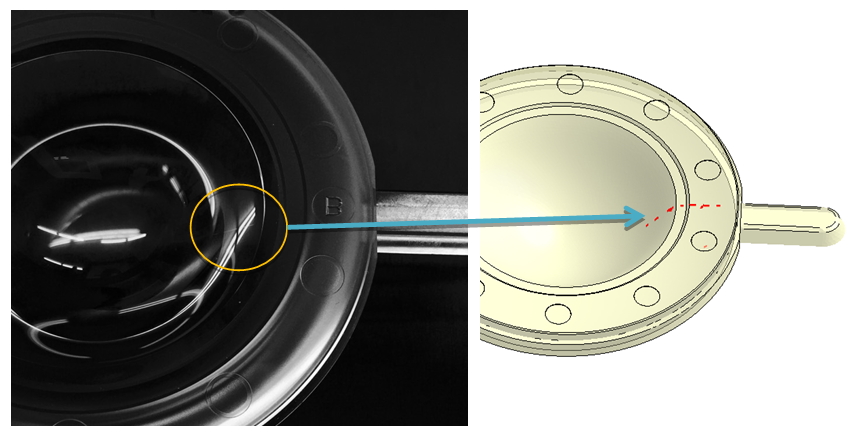

CALIN Technology applied Moldex3D to predict the hesitation and weld lines on their projector lens product. Through the simulation analysis, CALIN Technology was able to adjust and optimize the process parameters prior to real manufacturing to solve the weld line problem and improve product shrinkage. Utilizing Moldex3D Advanced to obtain optimum process settings in order to successfully resolve the product’s problem The objective of this case is to solve the weld line issue and reduce the cycle time of a projector lens product (Fig. 1). CALIN Technology decided to create overflow region and conformal cooling channels in order to achieve the goal. Although there are various methods to design the overflow zone and conformal channels, most of them would cost substantial mold production fees and time. Therefore, CALIN Technology utilized Moldex3D to simulate the molding scenario of the original design, overflow design, and conformal cooling channel design before an actual molding in hopes of achieving the most ideal design without excessive production cost. Through the simulation results, CALIN Technology found out that in traditional injection molding, weld lines would occur in the main region of the part and it might cause potential risks of product deformation. Furthermore, this molding defect would have a direct negative impact on the product’s functionality and physical appearance. Thus, CALIN Technology added an overflow region in the cavity in order to solve the weld line problem. According to Moldex3D simulation results of the revised design, the weld lines disappear in the obvious regions (Fig. 2). Next, to reduce the cycle time, CALIN Technology proposed using conformal cooling channel designs (Fig. 3). Through Moldex3D simulation results, the cycle time of revised designs does not show a significant improvement compared with the original design (Fig. 4), so there is no need to change the design of cooling channels. Through Moldex3D analyses, CALIN Technology could clearly understand the filling behaviors and predict weld line locations before an actual production. The accuracy of Moldex3D simulation analyses were also validated by the actual mold-trial results (Fig. 5). In the end, CALIN Technology was able to successfully solve the manufacturing issues and optimize their product and mold designs. Chrome Metal,Chrome Metal Packaging,Metal Chrome Metal Chrome-Plated,Chrome Metal Powder Ingredients SICHUAN YINHE CHEMICAL CO.,LTD , https://www.sichuanyhcc.com

![]()

Executive Summary

Challenges

Solutions

Benefits

Case Study

Fig. 1 The projector lens product in this case

Fig. 1 The projector lens product in this case Fig. 2 The weld line issue in the revised design with an overflow region has been improved

Fig. 2 The weld line issue in the revised design with an overflow region has been improved Fig. 3 CALIN Technology proposed using conformal cooling channel designs to reduce the cycle time

Fig. 3 CALIN Technology proposed using conformal cooling channel designs to reduce the cycle time Fig. 4 The cycle time of revised designs does not show a significant improvement compared with the original design

Fig. 4 The cycle time of revised designs does not show a significant improvement compared with the original designResults

Fig. 5 Moldex3D’s simulation results (right) of the weld line location on the original design

Fig. 5 Moldex3D’s simulation results (right) of the weld line location on the original design

is validated by the actual molding results (left)

Customer Profile